After reading some other posts here about the camoed Taslite nylon that WallyWorld has been selling, I bought 12yds for less than $16 and decided to make a tarp. I researched all the sizes & dimensions used by the vendors here, and kind of settled on my own plan, more or less an average of what's out there. All edges and the ridge are cat-cut, but not as deeply as some. I want maximum coverage but with the advantages of the cat edges.

I ended up with a ridge length just over 11' and side lengths of 56" at the tie-outs, sligthy less in the middle. Used some black nylon material I had to reinforce the tie-outs & both ends of the ridge line. Where I joined the two pieces of material at the ridge line, I came up with what I thought was a flat-felled hem, but later research online proved me wrong. It's all good though, since my version means that all stitching goes through four layers of material instead of just three.My sweet old Slant-o-Matic 404 did an absolutely beautiful job stitching it's way around this mass of fabric. Never missed a beat until I got a little hasty while attaching the straps and bent a needle.

Since this fabric isn't waterproof, I decided to whip up some DIY potion using what appears to be a popular recipe of silicone and mineral spirits. While I understand the hesitation of some folks here toward messing with this stuff, I'm the kind of guy who'd rather build than buy, so I just had to try it . . .

I pumped one full tube of GE clear silicone into a 5-gal bucket, and then used the now-empty tube to measure the precise amount of thinner. This exact ratio seems to be a mystery and even at times, the cause of heated discussion over too thin vs too thick. Well, the mystery is solved. The answer is 1-part silicone to exactly 3.75 parts thinner. How do I know?!? Because that's when I ran out of mineral spirits!The consistancy looked good to me, and it was just enough to soak the tarp and even wring out a little bit of leftover.

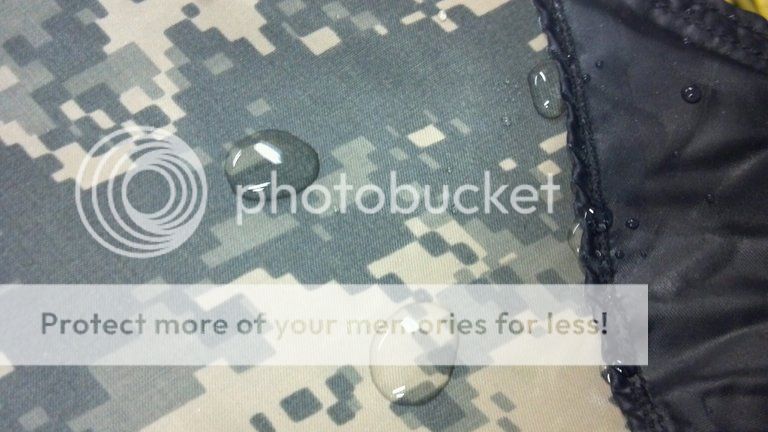

Seriously though, it seemed to penetrate the fabric well, and once the tarp was wrung & hung, I saw no globs whatsoever. I still took a sponge and wiped down the surface just to ensure eveness, but really didn't get much off. Although this job's a mess, I think immersion seems to be a better, more thorough way to saturate the fabric, as opposed to "painting" it on.

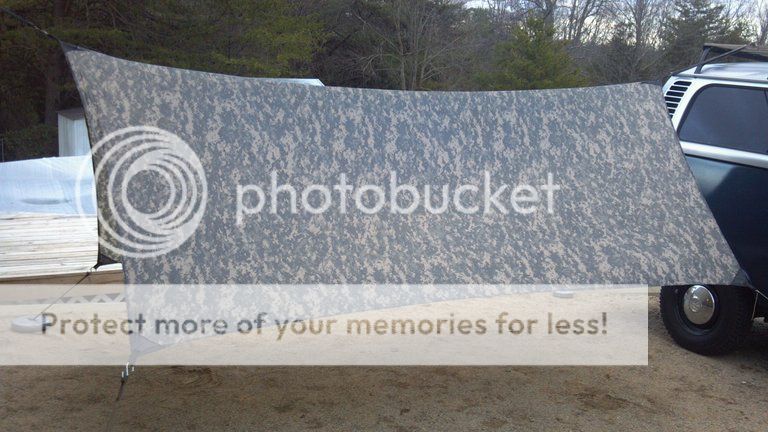

So here's the final product, freshly Sil'ed and hung to dry. Temps dropped from the mid to low 50's while this was out, but still only took about 2 hrs before I could handle it enough to rehang it inside the shop for an overnight cure.

Did a quick water test about 4 hrs later and had no soakthrough and good water beading on the surface. I'm anxious to get it out and see how it looks once properly hung the next nice day . . . more pics and water testing results to come!

-Klauss

Reply With Quote

Reply With Quote

Bookmarks